Essar Steel Algoma Inc. is preparing to build two treatment ponds to manage concentrations of dissolved iron in storm and surface water at its material storage and reprocessing site in Sault Ste. Marie.

"This is on the far side of our property. It's a development that's underway right now," says Brenda Stenta, Algoma's manager of corporate relations.

"We're treating dissolved iron, suspended solids that develop as a result of the dissolved iron, and we're neutralizing the pH [acidity or basicity] of the water," Fred Post, the steelmaker's manager of environment control, tells SooToday.

"Since we're an iron and steel producer, we have iron in our byproduct materials such as slags that would dissolve in the water as it runs across. We're capturing that water," Post says.

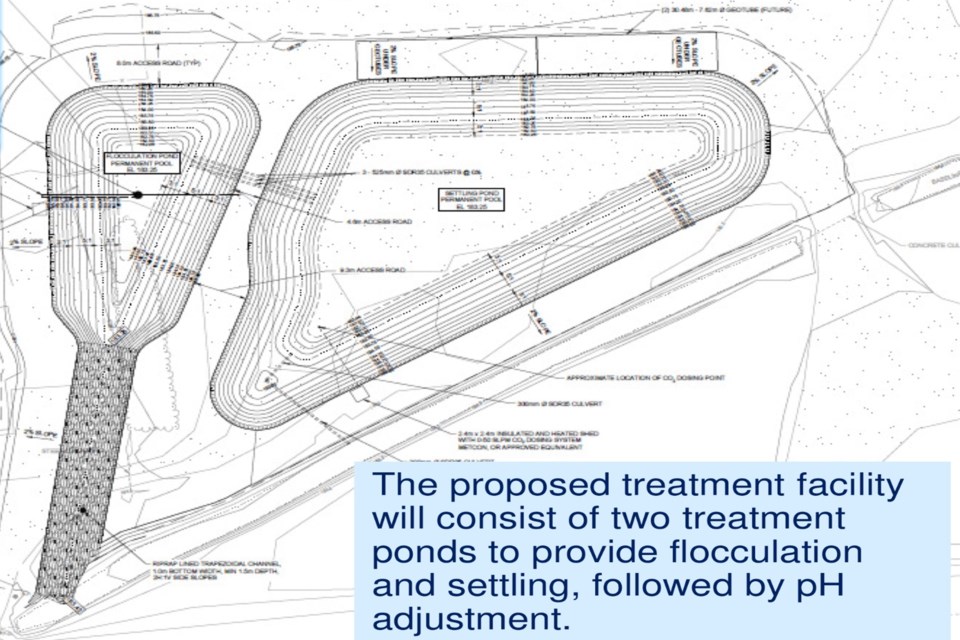

Algoma has proposed building two treatment ponds: one for settling and the other for flocculation – the process by which fine particulates are made to clump together to facilitate their removal.

A drainage ditch in the northeastern part of Algoma's material storage and reprocessing site currently serves as a catchment for groundwater and surface water run-off.

Tests done by the steelamker since 2014 have repeatedly found that pH, dissolved solids and total iron require treatment.

"There's actually very little contaminant in the water. It's very, very clean, especially at the pH that we see, the dissolved metals and things readily precipitate out of solution, so they've just got a high pH water that is very easily adjusted to a neutral state, and is allowed to discharge into Bennett Creek and ultimately the St. Marys River," Post says.

Algoma is submitting an environmental compliance approval application to the Ontario Ministry of Environment and Climate Change for the project.

"We're looking to be building this on our site in the next one to two years," Post says.

"The water that we're currently seeing is slightly basic. It's a very well-known technology for water treatment."

"The plan is to add a polymer and an oxidation system so there'll be a little fountain here to oxidize the iron, bind it into a smaller particle. A polymer is added to bind the particles together, make them heavier and settle out of suspension. That will happen in the ponds."

"From there, we would have a carbon dioxide sparging system, which bubbles carbon dioxide gas through the water and neutralizes the pH," Post said.

Details of the water treatment plan were unveiled by company officials at an environmental open house earlier this month at the Polish-Canadian Hall at 235 Goulais Ave.

Also disclosed by the Sault steelmaker:

- Algoma has spent approximately $20 million this year rebuilding one stove on its No. 7 blast furnace, which will reduce greenhouse gas emissions by 40,000 tonnes annually. The company is looking at other ways to further reduce its carbon footprint

- considerable attention is being paid to reducing cokemaking emissions. On July 2, 2015 the company began to monitor coke oven emissions in accordance with a new site specific standard. Other new limits came into effect on January 1, 2016 and again on January 1, 2017.

- charging emissions at the three batteries feeding the No. 7 blast furnace have been better than limit since February 2016

- on lid emissions, all three batteries are performing now better than the 2020 limit

- door emissions and off-take emissions are on track to achieve the 2020 limit ahead of schedule

- dredging of the boat slip was completed on Sept. 22. The three-week project removed what the company described as "legacy contaminated sediment." A post-dredge sediment assessment is planned to determine future plans

- as SooToday reported earlier this month, Algoma is proposing to build a 50-megawatt solar farm as one of three energy initiatives that will eventually allow it to generate half its total power requirement