Algoma Steel Inc. has already spent more than $100 million on a two-year, game-changing technology upgrade that local building officials say will be the most expensive construction job in Sault Ste. Marie's history.

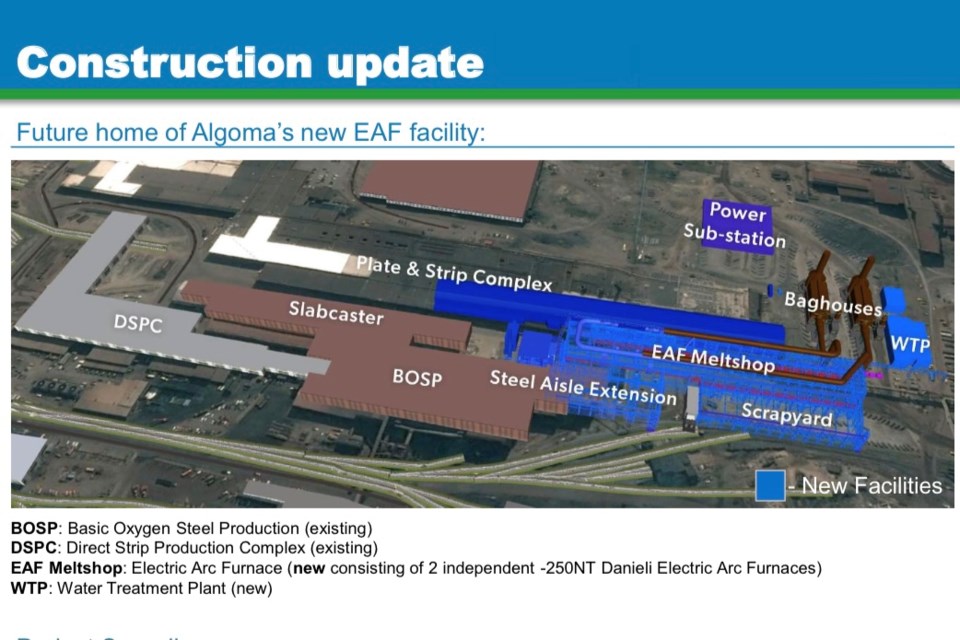

The massive project, expected to cost $703 million, will replace Algoma's existing blast furnace and basic oxygen steelmaking processes with two new electric arc furnaces (EAFs), allowing 3.7 million tons in annual raw steel production with something like a 70 per cent reduction in annual carbon dioxide emissions.

Michael Garcia, the steelmaker's president and chief executive officer, says the job is on schedule and on budget.

Foundation work is currently underway, Garcia says, and structural steel for new buildings should start to rise in late September or in October.

Chief building official Freddie Pozzebon, who's held pretty much every job in the city's building division over the past 34 years, tells SooToday he can't remember hearing of a more costly local build, at least since the municipality started issuing building permits and tracking construction values.

Prior to Algoma Steel's current project, the biggest building job in Sault Ste. Marie’s history was the new Sault Area Hospital, completed in 2011 at a cost of $408 million.

Algoma's conversion to electric-arc steelmaking could end up costing more than the budgeted $703 million.

Chief financial officer Rajat Marwah told investors during a conference call last week that an $80 million contingency fund has been assigned to the project and a small amount of that has already been committed.

"We will see a large part of the spending coming in the coming two quarters, up to December," Marwah said.

Detailed engineering work on the EAF project won't be completed until later this year, he added.

CEO Garcia mentioned during the same investor presentation that foundation and pilings work is currently underway.

"We expect to start erecting buildings – or things above the level of the ground – on October, late September."

"We had very little infrastructure or operations that were taking place in the footprint of the new EAF complex," Garcia said.

"What we did have was a relatively small ladle maintenance repair shop that we have relocated."

"Probably the biggest thing that we had was the internal railway tracks that we use to convey our hot iron from the blast furnace to the [basic oxygen steelmaking plant.]"

"We had to reroute that section of track. It's maybe a quarter-mile at the most. Move it off to the side of where the EAF is going to be constructed."

Sixty per cent of contracts related to the EAF facility have been signed, with 40 per cent remaining to be issued.

Walters Inc. has a contract for fabricating and erecting the main building structure for the EAF melt shop, in addition to the necessary dust collection hoods.

A long lead time is needed to order electric arc furnaces and two 250-ton EAFs have been ordered from Danieli & C. Officine Meccaniche S.p.A., to be powered by twin digital power systems from the same supplier with a rated capacity in excess of 190 million volt-amperes.

PUC is building a new 230-kilovolt local transmission line to service the furnaces.

GE Canada has been retained for gas-turbine upgrades to Algoma's internal power generation facility.

The project will also include a new water treatment plant.